Every bag tells a story — yours starts here.

Walk into any neighborhood café, stroll through a weekend music festival, or browse a boutique pop-up market — you’ll likely spot them: thoughtfully designed tote bags slung over shoulders, stuffed with books, groceries, or festival essentials. These aren’t just carriers; they’re quiet storytellers. A well-crafted custom canvas or cotton bag transforms everyday errands into moments of brand expression. And at the heart of this quiet revolution? Thermal transfer printing — a technology that doesn’t just print on fabric, but makes design an inseparable part of it.

When Fabric Begins to Speak: The Rise of Wearable Brand Narratives

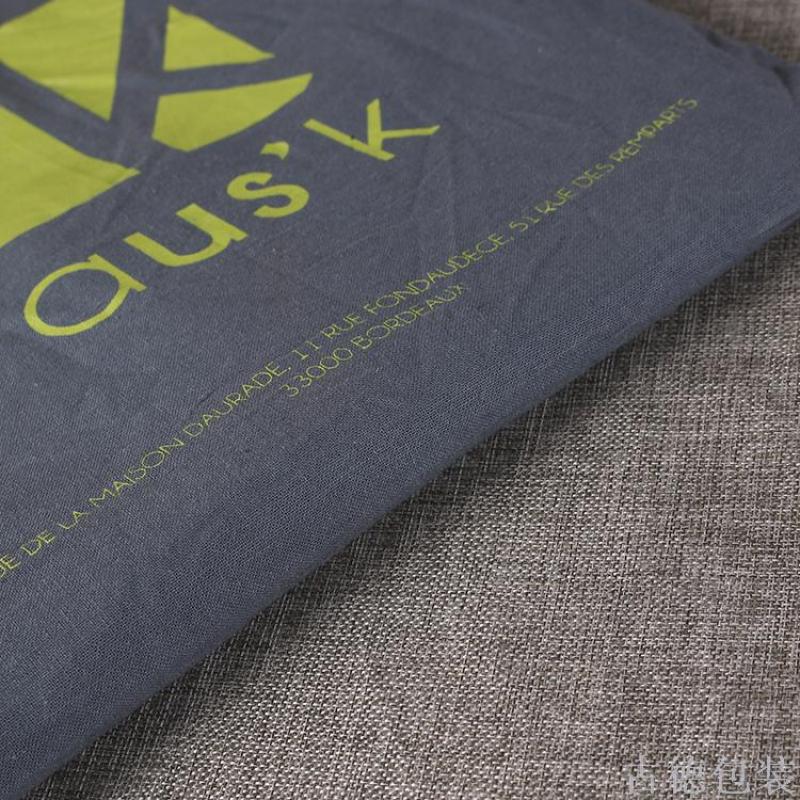

Gone are the days when tote bags were mere afterthoughts. Today, they walk like moving billboards — not in a loud, commercial way, but with subtle confidence. Whether it’s a minimalist logo from a local roastery or a full-bleed illustration celebrating seasonal art, these bags carry identity. With thermal transfer, intricate gradients, photo-realistic imagery, and fine linework merge seamlessly into the fibers, ensuring that every hue and shadow stays vivid wash after wash. It’s no longer about slapping a logo on cloth; it’s about letting your brand breathe through texture, color, and craftsmanship.

From sketch to shoulder: where art meets utility.

The Dialogue Between Material and Message

Not all fabrics speak the same language. Soft, breathable cotton whispers comfort and approachability — ideal for lifestyle brands, bookshops, or wellness studios aiming to connect on an emotional level. On the other hand, rugged canvas shouts durability and resilience, perfect for outdoor gear labels or urban fashion lines needing structure and strength. But beyond aesthetics, material choice today is a statement of values. As sustainability becomes non-negotiable, eco-conscious consumers gravitate toward reusable cotton totes as symbols of responsibility. Our factory-direct production ensures each batch meets strict environmental standards — from OEKO-TEX certified dyes to reinforced stitching tested under real-world load conditions. Every thread is chosen not just for look, but for longevity and conscience.

The Magic Beneath the Heat: How Thermal Transfer Transforms Design

Traditional screen printing often struggles with complexity — gradients fade, fine details blur. Thermal transfer changes the game. Using precision-controlled heat and pressure, ink sublimates directly into the fabric’s fibers, creating a bond that resists cracking, peeling, or fading. We’ve tested our prints through 50+ industrial washes — the colors remain bold, the edges sharp. This means your brand doesn’t just look professional; it stays professional. Even better, digital thermal transfer eliminates the need for costly plates or long setup times, making small-batch customization accessible. Whether you're launching a limited edition series or testing a new visual direction, high-end quality is now within reach — without minimum order anxiety.

Microscopic precision meets macro impact.

From Concept to Carry: The Journey of a Signature Tote

It begins with a designer’s vision — a vector file uploaded with anticipation. Our team performs meticulous color separation and alignment checks before printing the design onto specialized transfer paper. Then comes the transformation: the paper meets the bag under controlled heat (up to 200°C), transferring the image permanently into the weave. Edges are finished either by hand for artisanal appeal or machine-stitched for industrial consistency — a decision guided by your brand’s desired feel. One independent bookstore, for instance, launched a monthly “cover art” tote series featuring illustrations from classic novels. The result? A 38% increase in member renewals — proof that functional objects can become collectible emblems of belonging.

More Than a Bag: Redefining Brand Engagement

These totes do more than hold items — they extend brand memory. At trade shows, a well-designed thermal-printed cotton bag outperforms flyers or pens, serving as both gift and carrier, seen repeatedly in public spaces. For pop-ups, they act as walking invitations. For eco-focused brands, replacing single-use packaging with reusable printed cotton bags turns transactions into statements. Psychologically, people keep useful things. And when those things reflect personal taste or shared values, retention skyrockets. Your tote isn’t just handed out — it’s reused, noticed, remembered.

Where gifting meets sustainability and visibility.

Folding the Future: What’s Next for Custom Totes?

Innovation continues to unfold. Imagine thermo-chromatic inks that shift color with temperature, or localized UV gloss effects adding tactile dimension. Some pioneers are experimenting with touch-responsive coatings or modular straps turning one bag into many. Equally exciting is the rise of co-creation platforms — invite customers to design their own version, deepening engagement while gathering real-time feedback. And as urban lifestyles demand smarter solutions, compact, foldable commuter bags with personalized thermal prints are poised to dominate city streets. The future of custom bags isn't just about appearance — it's about adaptability, interaction, and meaning woven into every fiber.

Endless possibilities, ready to be carried forward.

Whether you're building a brand, launching a campaign, or reimagining customer experience, a custom-printed cotton or canvas tote made with thermal transfer is more than merchandise — it’s a message in motion. Durable, expressive, and deeply personal, it bridges function and feeling in ways few products can. Let your next bag say something worth repeating.