Imagine a world where every bag tells a story — not just of what’s inside, but of who carries it. In today’s culture of self-expression and conscious consumption, the humble tote has evolved into far more than a carrier. It's a canvas for identity, a statement of values, and increasingly, a powerful extension of brand presence. At the heart of this transformation are custom canvas and cotton bags, now elevated through advanced thermal transfer printing and direct-from-manufacturer sourcing.

When Fabric Meets Personality: Redefining the Art of Everyday Carry

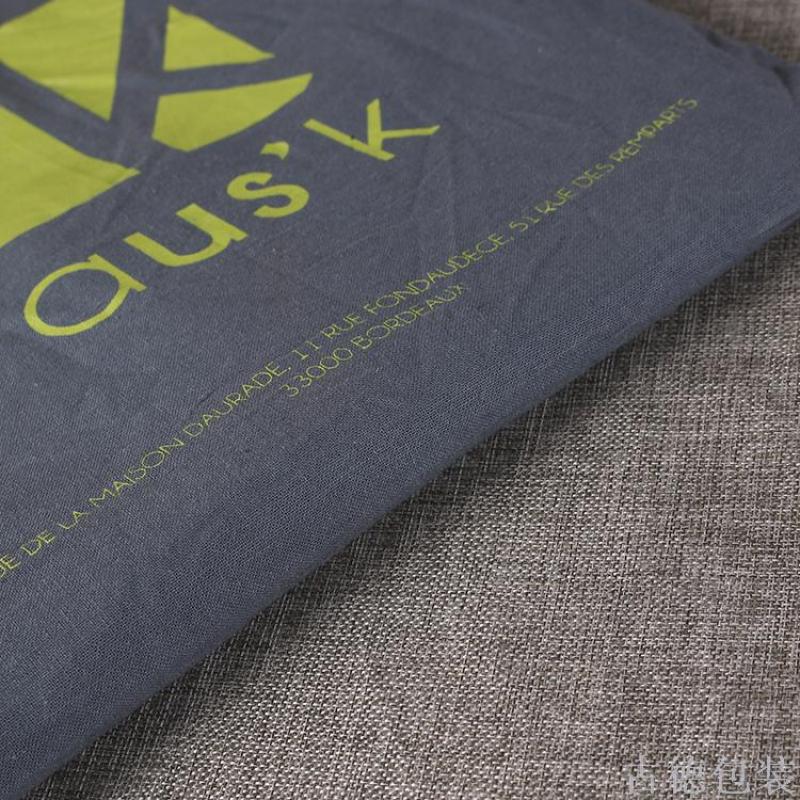

From streetwear enthusiasts flaunting limited-run artwork to eco-conscious shoppers rejecting single-use plastics, fabric bags have become central to modern lifestyle aesthetics. The blank surface of a cotton or canvas tote is no longer empty space — it’s an invitation. Whether emblazoned with bold typography, intricate illustrations, or photographic imagery, these bags serve as wearable art. And thanks to thermal transfer printing, even the most nuanced gradients and fine details can be faithfully reproduced, turning each piece into a wearable gallery.

The Power of Going Straight to the Source

Behind every standout bag is a supply chain that either empowers or limits creativity. Brands that partner directly with manufacturers unlock unparalleled advantages: reduced costs by cutting out intermediaries, faster turnaround times, and greater control over design execution. But not all factories offer the same level of reliability. True partners maintain a delicate balance between consistent quality control, scalable production capacity, and responsive communication. This triad ensures your vision isn’t compromised at any stage — from concept to cargo container.

Fabric Dialogues: Canvas vs. Cotton – Which Speaks for Your Brand?

The choice between canvas and cotton isn't merely aesthetic — it reflects function, durability, and brand ethos. Heavy-duty canvas stands strong in retail environments, outdoor events, and promotional campaigns requiring resilience. Its structured drape and weight convey professionalism and longevity. On the other hand, soft cotton offers breathability and a relaxed elegance, perfect for lifestyle brands, boutiques, or seasonal collections aiming for a light, approachable feel.

Beyond texture, sustainability is shaping material decisions. Organic cotton and recycled fibers are gaining traction among environmentally aware brands. These options reduce ecological impact while enhancing consumer trust — especially when paired with transparent sourcing narratives and low-impact dye processes.

The Magic Behind the Print: How Thermal Transfer Transforms Textiles

Thermal transfer printing isn’t just another method — it’s a game-changer. Unlike traditional screen printing, which struggles with complex color blends, this technique uses heat to infuse ink deep into the fabric fibers. The result? Colors that pop with photographic clarity, resist fading after repeated washes, and retain softness without cracking. Even intricate patterns, halftones, and full-color images reproduce with stunning accuracy. Best of all, the technology supports small-batch production, making it ideal for startups, limited editions, or test runs without minimum order pressure.

From Idea to Delivery: Mapping the Customization Journey

Creating custom bags may seem daunting, but a streamlined process makes it effortless. It begins with your design upload — digital files are reviewed for resolution and color mode to ensure print readiness. A sample is then produced for approval, allowing you to verify colors, stitching, and overall construction. Once confirmed, bulk production commences, followed by rigorous quality checks before packaging and shipping. Clear communication during sampling prevents common issues like shade mismatches or alignment errors, saving time and reinforcing confidence in the final product.

Bags That Broadcast: More Than Packaging, They’re Promotion

In retail and corporate gifting, a well-designed tote transcends utility. For retailers, it extends visual identity beyond storefronts — reinforcing logos, color schemes, and brand tone every time it hits the sidewalk. Companies distributing employee or client gift bags turn users into ambassadors; each commute becomes a mobile ad campaign. Collaborations with artists on exclusive cotton bag designs have also sparked viral moments on social media, blending collectibility with shareability in one sustainable package.

Sustainability as a Statement: Elevating Ethics Alongside Aesthetics

Reusable fabric bags significantly cut down on plastic waste and carbon emissions associated with disposable alternatives. When brands choose eco-friendly materials and ethical manufacturing, they don’t just do good — they look good doing it. Communicating this journey — from organic fiber sources to water-based inks and energy-efficient printing — builds deeper emotional connections with consumers who value transparency and responsibility.

The Future of Custom Bags: Where Innovation Takes the Next Step

What lies ahead? Integration of smart features like NFC tags for instant brand engagement, modular pouches for interchangeable designs, or user-driven platforms where customers co-create their own versions. As on-demand production grows, brands can move toward zero-waste models, producing only what’s ordered. The future of custom bags isn’t just about looking good — it’s about being agile, intelligent, and deeply aligned with evolving consumer values.

Your brand deserves more than a generic carrier. With direct manufacturer access, superior thermal transfer printing, and thoughtful material selection, your custom canvas or cotton bag can become a true reflection of purpose, style, and innovation. Step into the next generation of carryables — where every stitch and shade tells your story.