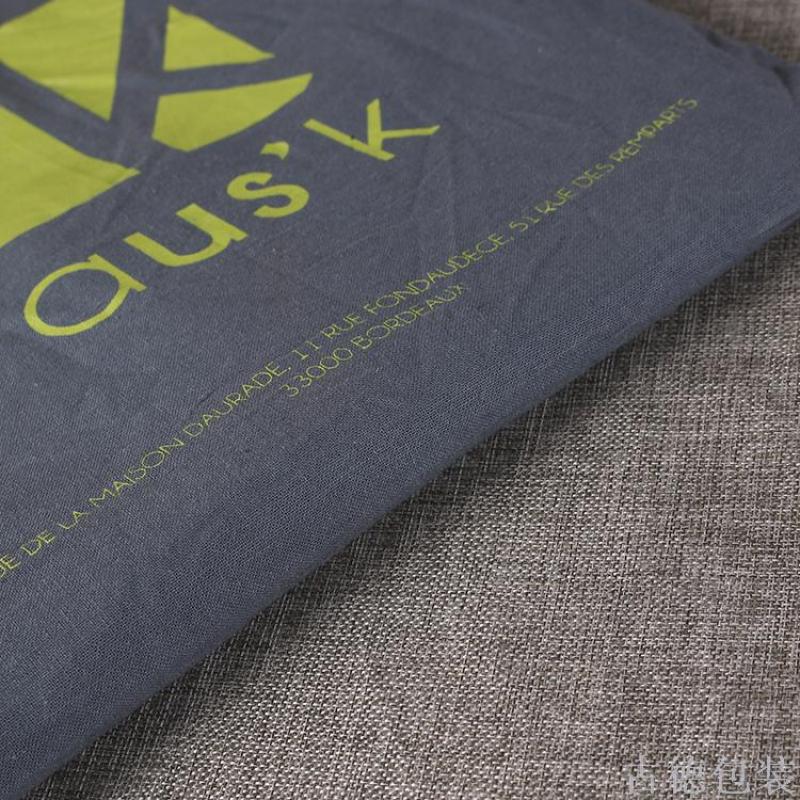

Custom Canvas and Cotton Bags from Manufacturers – Printed & Thermal Transfer Options

Picture this: a street artist strolls through a sunlit urban plaza, slinging a rugged cotton tote emblazoned with her bold signature strokes. A few steps behind, a café-goer exits with a hand-drawn logo dancing across their reusable canvas bag. These aren’t just accessories—they’re silent storytellers. When fabric meets imagination, every stitch becomes part of a brand’s journey. Custom canvas and cotton bags have evolved far beyond utility; they are now mobile billboards, wearable art, and powerful tools for identity.

Why Is Everyone Choosing Cotton and Canvas?

The rise of eco-conscious consumerism has brought natural fibers back into the spotlight. But what makes cotton and canvas stand out in a world flooded with synthetic alternatives? It starts with texture—soft yet sturdy, breathable yet resilient. High-density canvas offers unmatched durability, ideal for daily commutes or weekend markets, while organic cotton brings a gentle touch perfect for gift packaging or lifestyle branding.

Beyond feel, there’s a deeper story. Both materials are biodegradable, reusable, and leave a lighter footprint on our planet. From farm to loom, responsible manufacturers prioritize sustainable sourcing—selecting low-impact dyes, minimizing water waste, and ensuring ethical labor practices. The quality begins at the thread level: tightly spun yarns woven into dense, long-lasting fabrics that don’t fray after repeated use. This isn’t fast fashion—it’s thoughtful production built to endure.

How Heat Brings Art to Life: The Magic of Thermal Transfer Printing

If your design has gradients, intricate details, or photo-realistic elements, traditional screen printing may fall short. Enter thermal transfer technology—a game-changer for creative freedom. Here’s how it works: your digital artwork is printed onto special transfer paper, then fused onto the fabric using precise heat and pressure. The result? Vibrant colors, razor-sharp lines, and stunning depth that remain intact even after multiple washes.

Unlike silk screening, which requires separate screens for each color and large minimum orders, thermal transfer thrives on flexibility. Small batches, complex illustrations, and unlimited color combinations become not only possible but cost-effective. Whether it’s a surrealist mural wrapping around a shopper tote or a nostalgic family portrait on a travel pouch, thermal transfer turns vision into reality—with no compromise on fidelity.

Designed for Real Life: Where Function Meets Beauty

A great bag doesn’t just look good—it feels right. Behind the scenes, smart engineering elevates everyday usability. Reinforced stitching, padded shoulder straps, and interior lining prevent wear and tear, while optional waterproof coatings make these bags rain-ready. Some feature hidden pockets, zip closures, or modular compartments tailored for laptops, groceries, or festival essentials.

And because sustainability means convenience too, many styles fold neatly into themselves—transforming into pocket-sized companions when not in use. Lightweight yet strong, they slip effortlessly into backpacks or coat pockets, ready to replace single-use plastic whenever duty calls.

The Silent Marketer: How Custom Bags Build Brand Loyalty

In an age of ad fatigue, people remember what they carry. A well-designed tote creates visual repetition—seen at subway stations, grocery stores, and Instagram stories. That consistent exposure builds subconscious recognition faster than any paid campaign. Independent brands have leveraged limited-edition prints to spark social media buzz, turning customers into ambassadors who proudly showcase their purchases online.

For corporations, the shift is equally profound. Instead of disposable pens or keychains, forward-thinking companies now gift elegant, personalized canvas bags—useful, memorable, and aligned with ESG values. One thoughtful item can keep your logo in rotation for years.

Your Story, Your Design: The Rise of Personalized Totes

From wedding favors stamped with couple portraits to graduation bags featuring student doodles, personalization adds emotional weight. Now, platforms allow users to upload artwork, quotes, or pet photos—co-creating products that resonate deeply. With low MOQs (minimum order quantities), even micro-brands or event planners can produce 50–100 unique units without financial risk.

Go Direct: Why Factory-Sourced Beats Middlemen

By partnering directly with manufacturers, brands bypass markup layers, gaining better pricing, faster sampling, and full transparency. Reputable factories offer ODM/OEM support—from sketching bag silhouettes to designing custom hangtags—delivering end-to-end solutions under one roof. Rapid turnaround times ensure seasonal launches stay on schedule, while agile communication streamlines revisions.

What’s Next? The Future of Smart, Sustainable Bags

Tomorrow’s totes will do more than carry things—they’ll connect, adapt, and regenerate. Expect plant-based dyes, QR codes linking to supply chain histories, and even AR-enabled designs that come alive through smartphone cameras. Imagine a bag whose ink shifts color in sunlight, or a recycled canvas line with a buy-back program fueling circular fashion.

The era of generic merch is fading. In its place rises a new wave: meaningful, beautiful, and made to matter. Whether you're building a brand or celebrating a moment, the humble cotton bag has never held so much potential.